The Ultimate Guide to Wool Fiber: Benefits, Types and Uses

An Overview of Wool Fiber

Protein Fiber:

Animal hair consists of complex proteins. The coat of sheep and goats is essential for textile. Wool is an animal fiber of outstanding importance. It comes from the fibrous covering of sheep, goats, camels, etc.

For thousands of years, wool has been used for clothing and other textiles by different tribes and nations around the world. Till today wool fiber has great importance because of its unique natural properties that are absent in other natural and synthetic fibers.

Wool-producing countries:

The entire range of protein fibers accounts for only about 6% of world fiber consumption, whereas wool fiber contributes 90% of protein fiber consumption. The major wool-producing countries are- Argentina Australia, Britain, and England. Holland, Spain Germany, New Zealand South Africa, France, Canada, USA. Soviet Russia Pakistan, Iran, etc

Wool and Hair:

Wool and hair both are protein fiber that comes from the fibrous covering of sheep, goat, and camel Wool fibers have some special characteristics that are absent in hair Wool are short fine, curly, and elastic but hair are long coarse, less elastic, and no scale and stiffer than wool.

The Manufacturing Process of Wool:

Wool is a natural, multicellular; staple fiber that may be sheared from the living rural domesticated sheep or pulled from the hide Bar after the animal has been slaughtered for its sweet meet The sheep are sheared by early spring and the fleece is removed in one piece by expert shares,

Sorting: Wool sorting is done by well-skilled workers who sort according to fineness; length and sometimes the strength of fibers.

Scouring: It involves washing in warm soapy water several times to remove the natural grease of gum from the fiber and the saint dirt and dust.

Oiling: The wool fiber is treated with various oils including animal vegetables and minerals because unmanageable.

Gameting: The picking and shredding process of recycled and unused wool fiber is called garnering.

Carbonizing: After garnering, the wool fibers are put through a dilute solution of HCl or H₂SO, which destroys any vegetable fibers is called carbonizing.

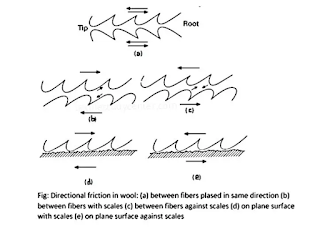

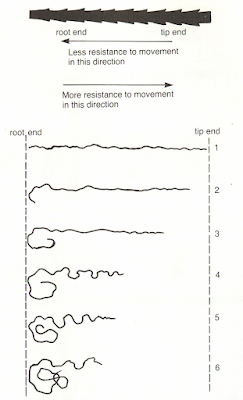

Felting of wool: When a fabric made from wool fibres is wet and is subjected to a suitable effective mechanical treatment of some sort such as rubbing: pressing and squeezing. Twisting or pounding. Wool felts because of their serrated surface structure or over-lapping epithelial cells but they are removed in one direction only to root ward due to less friction.

Morphological Structure of Wool:

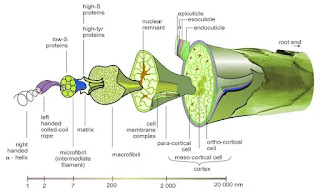

The morphological structure of wool fiber is extremely complex. The wool fiber exhibits wide variations in physical characteristics such as diameter and length. Its diameter can vary from 18-40 um along its length. The staple length of fibers removed from sheep varies greatly depending on a large number of factors such as the breed of sheep and the position of the fibers on the skins: From the morphological standpoint each individual wool fiber is divided into three sections.

The root: It is the living part situated beneath the surface of the skin.

The shaft/steam: It is cylindrical and tapers to a point at its free end.

The tip: The free end of the fiber is naturally pointed. While the tip from the mature fleece is flat indicating that it has been. previously shown

In a typical Wool fiber, there are 10 district regions, which can be distinguished readily through the microscope.

a) The Outer Sheath or Epicuticles

- This is the outermost layer and is a thin, water-repellent

- It is the only non-protein gait of the five and it protects the fibre like a covering of wak

- The membrane repels water and in this sense acts as a waterproof coating on the fibre membrane.

- The epicuticle is, however, permitted by many microscopic pores, through which water vapor may penetrate into the interior of the fiber,

|

| Fig: A Morphological Structure of wool fiber. |

- Wool fabric will thus aber water vapor from the body Without feeling damp and will release it again slowly into the air

- The outer membrane is easily damaged by mechanical treatment.

- Beneath the epicuticle layer of flat, scale-like cells that overlap like the shingles on a roof.

- The free ends of the scales point towards the tip of the fiber.

- The epicuticle and scaly layer together form the cuticle of the fiber.

(c) The Cortex:

- Enclosed within the cuticle is the cortex which consists of millions of long spindle-shaped cells, thick in the center, and tapering to points at each end.

- These cortical cells are 100-200 microns in length and 2-5 microns wide.

- These cortical cells are themselves built up from fibrous components called fibrils.

- These cells are found in lesser quantity in fine wool fibers (about 20 cells) than the coarser wools (about 50 cells) across the diameter of their cross-section.

- The cortex of wool fiber is composed of two distinct sections, namely Orthocortex and Para cortex', which differ from each other slightly in their physical and chemical characteristics.

(d) The Medulla

- A hollow space running lengthwise through the center of many wool fibers, especially the coarser fibers, is called the medulla.

- The presence of the medulla contributes to thermal insulation and also increases the light-scattering properties of fibers.

- It also causes some deterioration of fiber quality. These are

- -Medullated fiber suffers from Jower bundle strength.

- -They cause lower spinning properties.

- -They produce lighter shade than the true wool fibers.

Chemical Composition of Wool:

Raw wool contains a variety of different chemicals and dirt that must be removed. These impurities may comprise as much as 60% of raw wool mass. They include wool wax, suits, and a range of vegetable and mineral debris.

Approximate composition of raw wool

Component %

Wool keratin 33%

Wool-grease 28%

Suint 12%

Water 1%

Debris 15%

Other Impurities 26%

The wool fiber is chiefly composed of a protein called keratin. The elemental composition of wool keratin is the same in different types of wool. Wool keratin contains the following elements:

Elements %

Carbon 50

Oxygen 22-25

Nitrogen 16-17

Hydrogen 7

Sulfur 3-4

Chemical Structure of Wool:

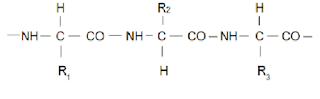

The wool fiber can be simply/described as a polypeptide, which is, produced through condensation of carboxyl and amino groups of 18 different amino acid residues as monomers having the general formula as given below: R-CH-COOH

NH2

These amino acids are linked to each other using peptide bonds (-CO-NH-) to form the peptide chain.

|

| wool fiber chemical structure |

Different bonding in wool fiber:

Polymer system in wool fiber:

Classification of wool (by sheep):

- The merino, the most important of all the sheep used as a source of wool, produces fine and soft wool.

- Short staple length ranging from 1-5".

- High scale per inch (about 118 per mm) and good felting properties.

- The merino sheep has been reared in Australia, South Africa and South America, New Zealand.

- Quality almost same to class-1 but length is a little bit higher (2-8)"

- Mainly produced in England, Scotland, and Ireland.

- Origin of this wool in the U.K.

- The length of this fiber is 4-8"

- Coarser, fewer scale and crimp, and less elasticity.

- Mostly used in garment-making

- Mainly cross-bred wool

- The length of this fiber is 1-16"

- Coarser and hair-like.

- Fewer scales and crimps and very little elasticity

- Used in carpet and blanket making.

- The first fleece sheared from young sheep is known as lamb's wool.

- This wool is clipped at eight months.

- This wool is very fine and of excellent quality.

- Produced garments are soft and comfortable.

- Not too strong.

- Fleece is sheared from fourteen months old sheep that have not been previously shorn

- The wool is stronger, finer, and elastic.

- Desirable wool and used as warp yarn

- Altogether, a sheep, on average, will provide between 0.9 to 4.54 kg of wool per year, according to breed.

- Any fleece clipped after first shearing is called weather wool

- Wool is sheared from 14 or more years of wool

- Dusty wool.

- When sheep are slaughtered for meat, their wool is pulled from the pelt by the use of chemicals (Lime or Sodium sulphide).

- Less quality wool due to the use of chemicals.

- The wool has been recovered from the sheep that have died or have been accidentally died.

- Very low quality.

- Used in cheap garments.

- Sheep that are exposed to severe weather conditions or lack of nourishment yield wool that is matted or felted.

- The torn, ragged, or discolored parts of a fleece are known as taglocks.

Physical properties of Wool:

- Length and fineness: Merino wool fibers are very fine (17-25 um) bill not very long (60-100mm) whereas Lincoln wool is coarser (around 40μm) in diameter but much on r. 75-250 mm).

- Crimp: The crimp of wool fibers is most pronounced in the fine wool fibers The best merino wools, for example, will have 30 waves per inch. The elasticity of wool fiber is due to its crimp. Due to its crimp, wool yarns trap air and when used in garments, provide an insulating barrier to loss of body heat.

- Luster: Wool fibers have natural luster, which varies in its characteristics, Depending on the type of wool, Luster depends very largely on the nature of the fiber surface.

- Tenacity: Wool has a tenacity of 8.8-15 cN/tex (1.0-1.7g/den) in a dry state and 7-14 cN/tex(0.8-1.6g/den) in the wet state.

- Elongation: Wool has an elongation at a break of 25-35% under standard conditions and 25-50% when wet.

- Elastic property: Wool fibers are highly elastic and resilient. The elastic recovery of wool fibers is 65% for 20% extension and almost 100% for short extensions.

- Specific gravity: Wool is a light-weight fiber with specific gravity of 1.32

- Effect of moisture and water: Wool fibers are hygroscopic and the most hydrophilic of textile fibers. Under ordinary atmospheric conditions, wool will hold 16-18% of its weight of moisture.

Chemical properties of Wool:

- Effect of acid: Wool is attacked by hot concentrated H.SO. and decomposes completely, It is in general resistant to other mineral acids of all strength, even at high temperatures, though nitric acid tends to cause damage by oxidation.

- Effect of alkalis: The chemical nature of wool keratin is such that it is particularly sensitive to alkaline substances, Wool will dissolve in caustic soda solutions that would have little effect on cotton fibers. Ammonium carbonate, borax, and sodium phosphate are mild alkalis that have minimum effect on wool.

- Effect of bleaching:

- Oxidizing agents: Oxidizing agents cause considerable change in the composition and properties of wool attacking preferentially in crystalline linkage. For bleaching purposes, hydrogen peroxide is commonly used as an oxidizing agent.

- Reducing agents: Wool is most strongly attacked by reducing agents in an alkaline solution they attack preferably on crystalline linkage.

- Effect of Organic solvents: Wool has a good resistance to dry-cleaning and other common solvents.

- Insects: Wool is attacked by moth grubs and by other insects.

- Microorganism: Wool has a poor resistance to mildew and bacteria and it is not advisable to leave wool for too long in a damp condition.

- Dye ability: Easy to dye. Acidic mordant-nature in metalized, Reactive dye is suitable

- Effect of heat: Wool becomes weak and loses its softness en heated at the temperature of boiling water for long periods. At 130°C it decomposes and turns yellow, and it chars at 300C As it decomposes, wool gives off a characteristic smell, similar to that from burning feathers.

- Wool does not continue to burn when it is removed from a flame

- The action of sunlight: The keratin of wool decomposes under the action of sunlight, a process that begins before the wool has been removed from the shsulfure sulphur in wool is converted into sulphuric acid; the fiberdiscoloredscoloured and develops a harsh losesIt losses strength and the dyeing properties are affected.

Felting properties of wool:

- The tendency of wool to feel is a distinctive property that is not found in many other textile fibers. The scaly layer of wool fiber is responsible for this property.

- Washing of woolen articles causes irreversible shrinkage and felting

- Mechanical compression and relaxation of the fibers in a woolen fabric during washing allow the edges of wool fibers to migrate only in the direction of the root end. The migrated fibers,theiring to its scale structure are interlocked with each other preventing the fiber from returning to its original position. This irreversible shrinkage is called felting.

- It closes up the fabric structure, making it much more compact and has increased rigidity.

Shearing of wool:

- On large-scale production, power-operated clippers remove the fleece.

- Inefficient hands, the sheep is parted from its wool in two and a half mfirst-classirst class sheerer can shear two hundred sheep in a day, from which he will clip a tonne or more wool. This type of wool is known as Fleece or clip wool."

Comments

Post a Comment