Study on Dyeing of Cotton Fabric with Direct Dyes

Dyeing of Cotton with Direct Dyes

Direct dyes are also sodium or potassium salts of colored and behave the same ways as acid dyes. These dyes are used to impart color name to the fabric hence the name

NaD = Na + D

Objectives of Dyeing

1) To provide color.

2) To obliterate the surface.

3) To develop newer designs as per the market requirement.

4) To improve the weathering properties and durability,

Nature of Sample: 100% pretreated cotton fabric

Apparatus Required for Dyeing:

- Glass Rod

- Beakers

- Pipette

- Aluminum vessel

- Thermometer

- Gas burner

- Tripod Stand

- Electric Balance

- Cylinder for measuring

Recipe Required for Direct Dyeing:

Sequestering Agent - 1cc/L

Na2CO3 - 5gm/L

Dyes -0.5%

Temperature -Boiling.

Salt- 15gm/L

M:L -1:70

Time- 30 minutes.

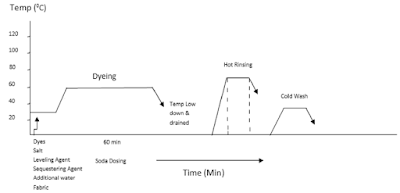

Process Sequence of Dyeing:

- A 100 % pretreatment sample is needed to start the dyeing

- Dyeing at 100 degrees for 20 minutes with direct dyes

- After treatment

- Cold rinsing

- Hot Wash

- Cold rinsing

- Drying

Function of Used Chemicals

Sequestering Agent - It reacts with a metal ion (Ca++, Mg++, Fe++) and removes the hardness of water.

Dyes - Modifies the color by decreasing its luminosity by the amount specified in the parameter.

Sodium Carbonate - It is used to hold the pH in 9.

Salt - It acts as a catalyst that accelerates the dying action.

Working Procedure of Direct Dyeing of Cotton Fabric:

After mercerizing the fabric weight. Then, we take water which is seventy times greater than the weight of fabric. We carry on the overall dyeing process into an aluminum vessel where the fabric emerges. After that, we took a particular amount of sequestering agent, Sodium carbonate Then we added one-third of the salt two times after 5 minutes. After 20 minutes, the fabric is taken away from the mixer for washing and dyeing

Calculation of Dyeing:

Weight of fabric = 11.73gm

Water - 11.73 * 70 =521.1mL

Sequestering Agent- 821.1/1000 = 0.821.1 mL

Na2CO3 = 5 * 821.1 = 4.105 gm

Dyes = 0.5 * 11.73/ 100 = 0.05gm

Salt= 15* 821 1/1000 = 12.31gm

Pre-caution:

1) Before evaluating chemicals the wt. measuring m/e must remain zero.

2) Overall dyeing Process should be done in an aluminum vessel

3) The amount of used chemicals should be counted properly.

4) The overall dyeing process above the heater must be done in about 30 minutes

Conclusion-

Dyeing is one of the important processes for producing buyer-required garment goods. From this experiment, we know how to dye bleached fabric with direct dyes.

Comments

Post a Comment